For over 200 years, the wooden pencil has been a writing utensil synonymous with back-to-school season, learning and education. It allows us to make mistakes and fix them; it allows us to brainstorm ideas and scribble down streams of consciousness; and it allows us a small reprieve from such a digital-centric world, if only for a moment while writing down a grocery list.

There are only three pencil factories left in the U.S., and Musgrave Pencil Co. is one of them. It has been in business for over 100 years, founded in 1916. Musgrave makes 72 million pencils a year and roughly 325,000 pencils a day from its factory in “The Pencil City.” That is a “small drop in the pond,” as many pencils in the industry these days are made overseas. But it has a large impact on the entire Bedford County community.

Musgrave Pencil Co. founder James Raford Musgrave began his pencil-making journey by bartering with farmers, offering to replace their old cedar fence posts for metal fencing. Doing so provided him with a supply of Eastern red cedar, an ideal wood to make into quality pencils.

Today, Musgrave Pencil Co. continues to be a family business, now on its fourth generation of family involved in the company. Musgrave President Scott Johnson said that being family-owned is a very important part of Musgrave Pencil Co.’s success and is how the company has continued to stay in business while many publicly or shareholder-owned pencil companies in the U.S. sold, went out of business or transitioned overseas in the 1990s and early 2000s.

There are over 100 steps in the process of making a pencil, from harvesting materials to the finished product, but the general process involves grooving wood, gluing, shaping, painting, imprinting, tipping and quality control, a process gone into some detail in the “How a Pencil is Made” blog post and videos on the Musgrave website.

Johnson said every step is important to make the finished product, but he particularly highlighted the first three steps done within Musgrave’s pencil factory — the wood department’s grooving, gluing and shaping of the pencils.

“I think the wood department is not only interesting, and not only embodies a great deal of precision, it’s also the most critical because if you don’t get that right, nothing else gets right,” Johnson said.

Musgrave Pencil Co.’s predominant supply of wood right now comes from basswood, but it still offers some specialized pencils like the retail option of “Tennessee Red” pencils made from Eastern red cedar, a nod to Musgrave’s beginning bartering with farmers for a type of wood that is prevalent in the Southeast.

In the wood department, the process starts with simple slats that run through a machine called a “groover,” which provides the foundation for the graphite. The cores are then laid down in the grooves, with another slat added on the top like a sandwich. They’re clamped together, and once the glue is dry, the pencil slats are shaped, one side at a time, into individual pencils, prepped and ready to be painted. Musgrave makes a variety of shapes of pencils: Some are round, some are hexagonal and some are even more rectangular like the carpenter pencils.

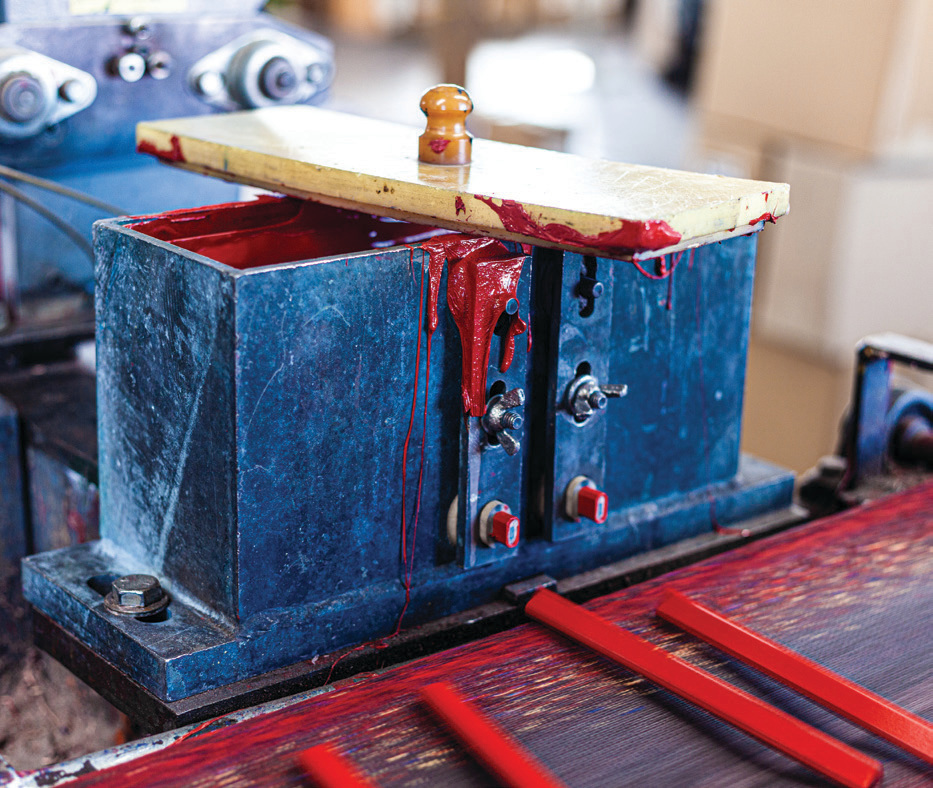

Pencils are coated up to seven times with either paint or varnish, and they go round and round on a painting machine until those coats are done. Some pencils get wrapped in a design, a process that Johnson said is very intricate and requires a lot of precision since it’s easy to misalign the designs. Imprinting can also add to the pencil’s visual appeal, with pencils often sporting words and logos made from a hot foil stamping machine.

Tipping is the next step, and it’s really three steps in one: the ferrule (metal part that holds the eraser) is added, then the eraser is added and the ferrule crimped to ensure the eraser won’t fall out.

“As the basic building block, the success of every step is a prerequisite for the next step,” Johnson said.

With each step, there is a margin for error, and Musgrave Pencil Co. knows this and does its best to catch potential errors as early as possible. After each step of the process, an employee performs quality-control checks before the batch of pencils moves to the next step. Quality is an integral part of Musgrave Pencil Co., and, while Johnson admits that it isn’t always perfect, Musgrave works hard to create a high-quality product.

“We stay true to our identity, and the parallel there is staying true to processes that work well,” Johnson said. “There’s the old adage, ‘If it’s not broke, don’t fix it.’ It’s also a reflection of the commitment of the staff.”

Musgrave Pencil Co. employs around 100 people at any given time, with around 80 in the plant and roughly 20 in administrative and supervisory roles.

Customized pencils are a trend that Johnson has noticed in recent years, and, as he called it, pencils are the “world’s smallest billboard,” a potential for a business to advertise.

A significant percentage of Musgrave Pencil Co.’s business comes from making customized pencils for a wide variety of clients, some being big-name businesses that are household names.

“In a small way, we’re part of their journey, and that’s really gratifying,” Johnson said.

Another industry trend Johnson has noticed is scented pencils, and Musgrave has worked with Melissa Bernstein, from the toy company Melissa & Doug, to help her make a customized order of essential-oil-scented colored pencils with rub-and-sniff technology on the pencil wraps for her Lifelines collection focused on well-being and stress relief using all senses, according to the Lifelines website.

Looking to make a customized pencil with Musgrave? The average customized order size is 18,000 pencils, but the minimum quantity is 100; while that small of an order does come with some customization limitations, the ability to do so truly is a testament to this smaller, family-owned business being able to accommodate a wide variety of clients and needs for those who want to support Musgrave’s American-made products.

“The pencil is ultimately a wonderful form of expression, and we use the word expression in many different scenarios. It’s an expression of learning, expression of creativity, expression of thought, expression of art; it’s actually even an expression of construction,” Johnson said, referencing Musgrave’s carpenter pencil, which is a popular product in the lineup.

Johnson said despite newer technology like artificial intelligence, ChatGPT and iPads, there is a basic need to be able to freeform create, and the pencil is at the center of that.

“I believe we’re here to stay, and that there’s a lot of opportunity for the pencil to play a big role in our culture and mindset,” Johnson said.

Pencils are a popular symbol used when it comes to education and back-to-school season.

“Back-to-school involves learning, and learning involves making mistakes and correcting them. So what better appliance than to have a pencil and eraser to be able to navigate learning?” Johnson asked.

Pencils aren’t just used in a school setting or for professionals like carpenters, though. Johnson said there are many reasons why adults should pick up a pencil instead of a pen, beyond doing so out of nostalgia for school days past. Pencils are flexible and versatile, offering the option to sketch lightly or write in bold, dark letters.

Sustainability is a huge piece of the argument for using pencils over their alternatives; there is a lot of single-use plastic waste involved with pens.

Nicole Delger, founder and CEO of Studio Delger who works with Musgrave Pencil Co. on graphic design and product development, said that sustainable practices are a through-line that continues to be part of Musgrave’s story today.

Musgrave’s Greenbelt pencils are even more environmentally friendly than the average pencil; they come with a Forest Stewardship Council certification that guarantees each pencil comes from a sustainably harvested source.

Musgrave also has sustainable practices within its factory; manufacturing creates 3.5 tons of sawdust each day, and the factory has partnered with a local equine supply store that provides bags to be filled with sawdust that the supply store can sell to horse stalls and farms in the area rather than the sawdust ending up in a landfill.

“There’s actually a really beautiful tie-in to our origin story because that’s how Mr. Musgrave started. He was upcycling, taking old fences down and using that to create a new product,” Delger said.

This back-to-school season, Johnson recommends looking under the “School Line” section of the Musgrave e-commerce website to see the different fun-themed and holiday pencil packs, finger fidget pencils and the standard classroom pencil.

Delger said the 60-count pencil pack is the best seller among teachers and also recommends the sustainable Greenbelt pencils; both are currently on sale on Musgrave’s website.

And you can’t go wrong with the Tennessee Red pencils, of course.

Johnson said, “We’re committed to the timeless product of the past as a way to create expression in various forms and to be a great alternative to the digital age while also embracing the digital age in our presence as a company.”

The best way to purchase a Musgrave pencil or start a customized pencil order is through the company’s retail website, musgravepencil.com. You can also follow @musgravepencil on Facebook or Instagram for updates on Musgrave Pencil Co.